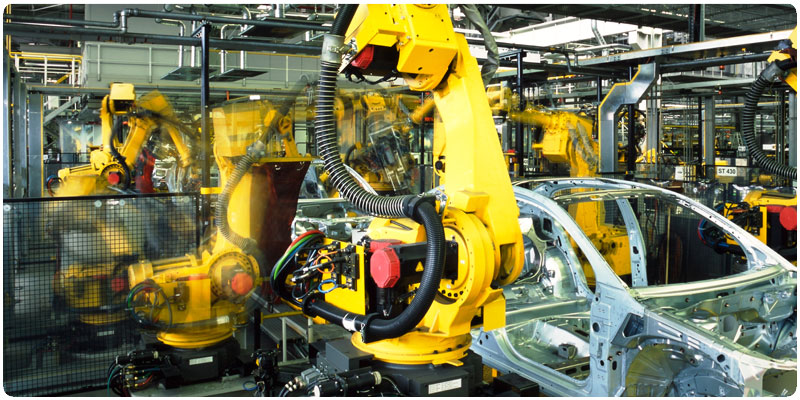

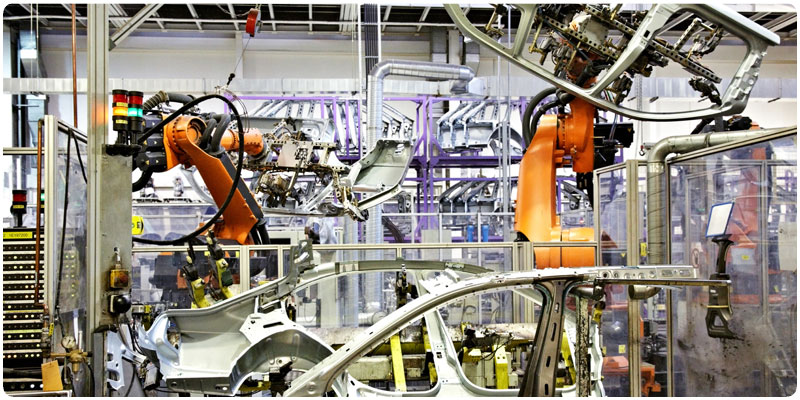

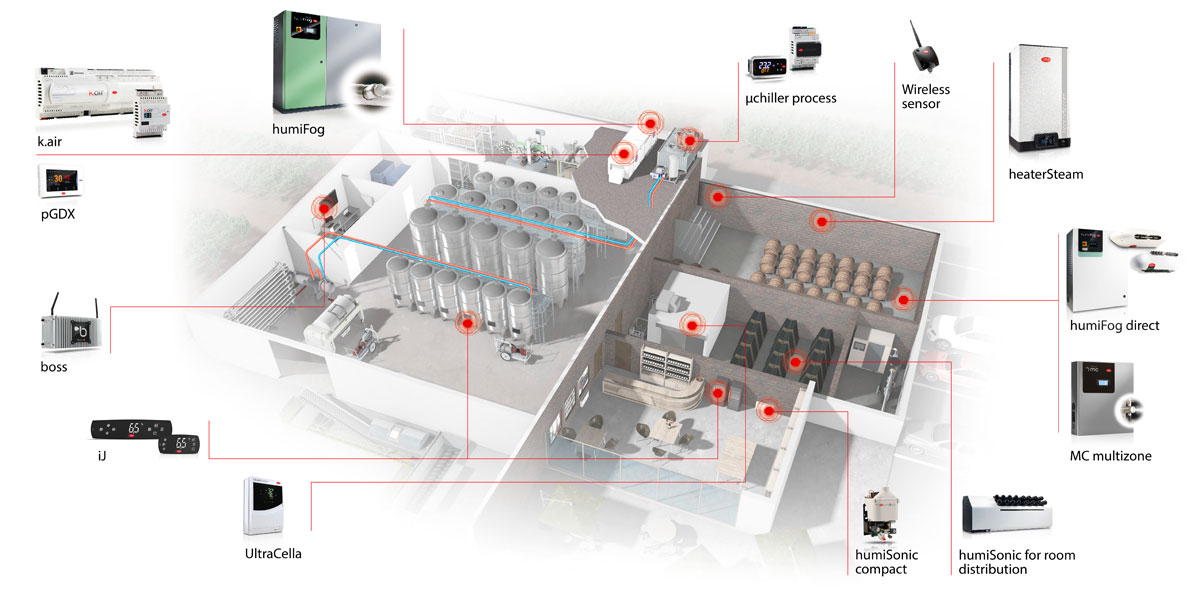

The automotive and aeronautical industries have seen considerable drive for continual improvement of production processes. The main companies in the industries are shifting their focus to higher quality and more environmentally-friendly manufacturing.

The introduction of water-based paints for vehicle bodies means control of temperature-humidity conditions in the paint booths is essential.

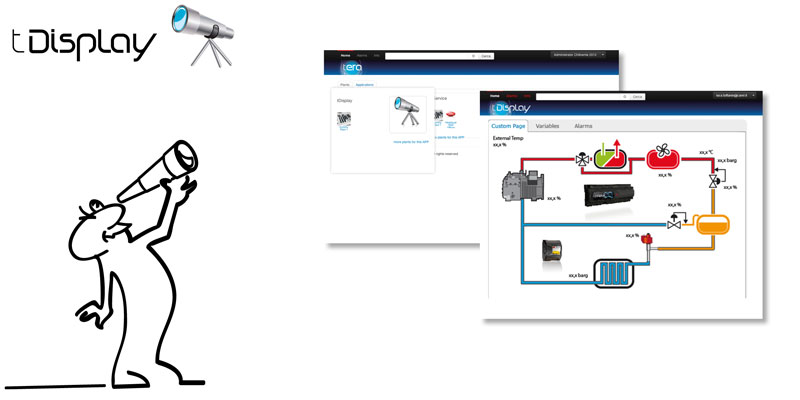

Air humidity that is too high causes excessive dilution of the coat of paint on the body, consequently causing the formation of minute "pockets" of liquid, that, after drying, may lead to defects and the formation of small craters on the surface.

Vice-versa, humidity that is too low may cause excessive evaporation of the water used to dilute the paints, making it much harder to apply the product and increasing paint consumption to ensure the minimum correct thickness of the coat.

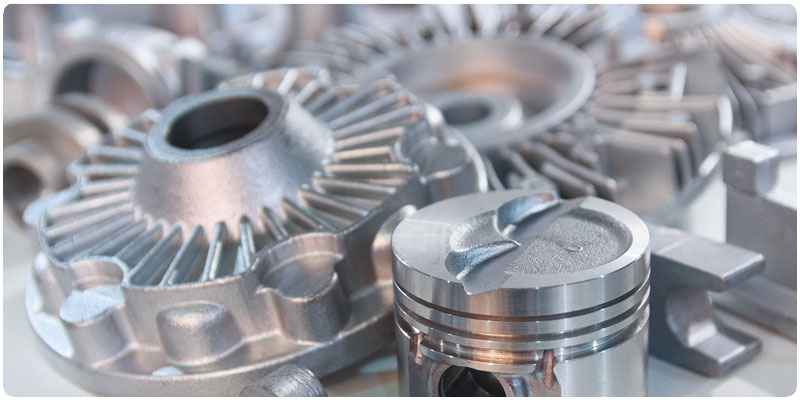

The automotive industry also features the use of new-concept materials. In particular, the processing of composite materials (such as carbon fibre) has become more and more common.

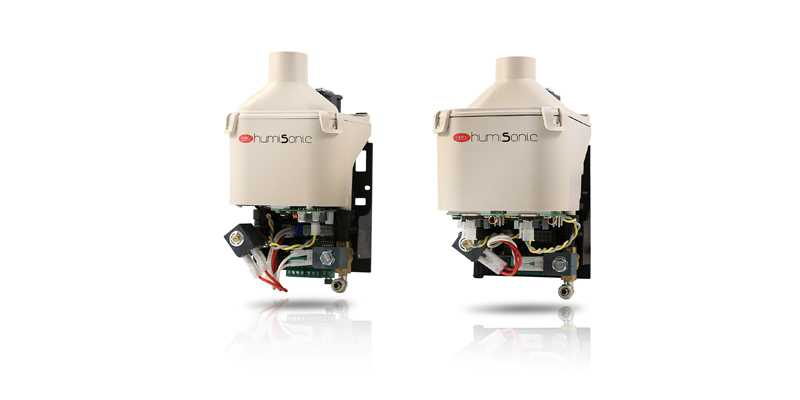

To ensure correct handling of such materials, absolute and precise air quality control is requirements in the production environment, including air humidity. Very high precision and reliability are thus fundamental requirements of the humidifiers used.

Another typical application in the automotive sector involves test chambers. Inside these special rooms, extreme climatic conditions are created (up to 95 % rH), with very tight limits in terms of tolerance and precision. In this way, the mechanical and electrical components are stressed to the limits, in order to test behaviour and verify functioning.

In industrial environments that use very sophisticated equipment and systems, the risk of electrostatic charges forming needs to be minimised.

To prevent build-up, it is important to ensure a humidity level above 30%. Low relative humidity makes discharges more likely, which may strike and damage the machinery.

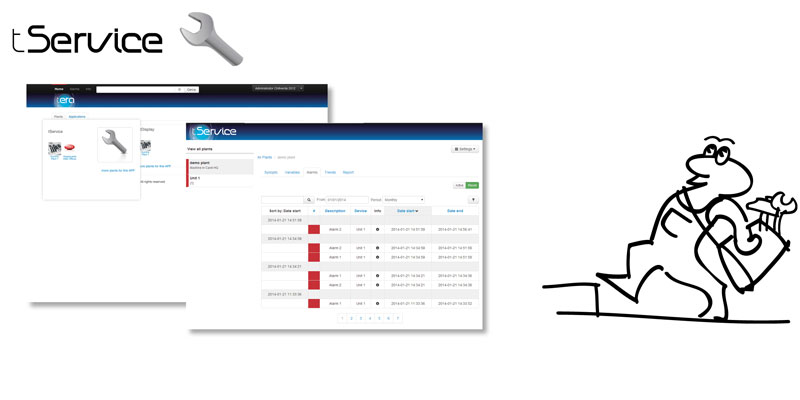

The right humidity level is also needed to ensure comfort for production workers. Keeping relative humidity between 40% and 60% ensures optimum conditions for personal comfort, reducing absences due to worker illness, above all in winter months.